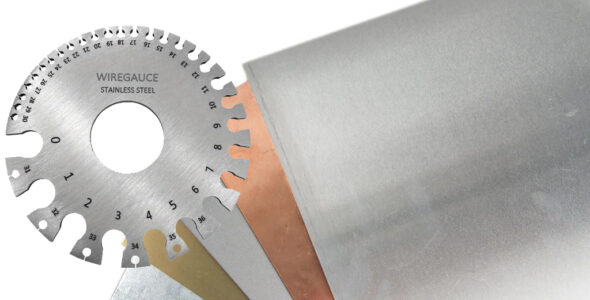

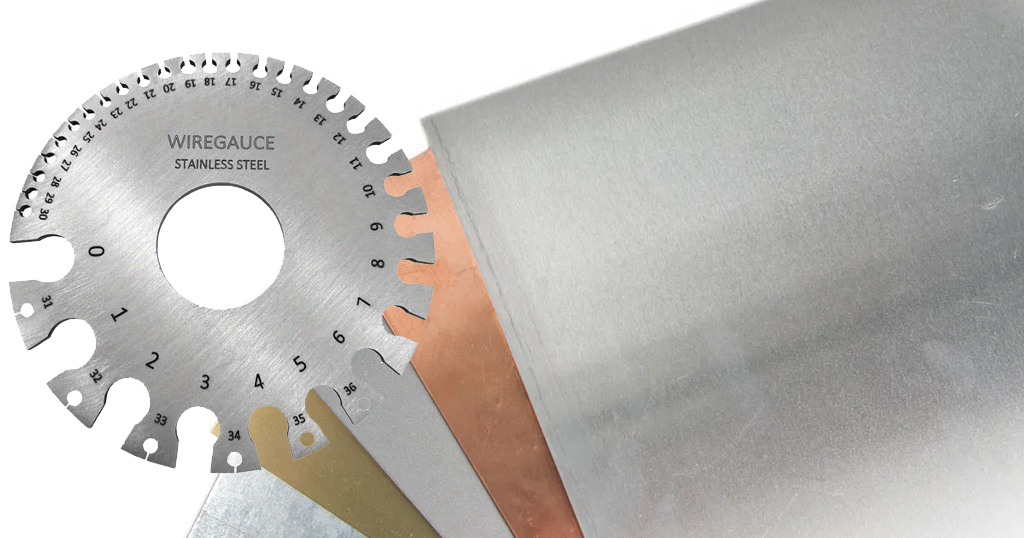

When it comes to crafting nature-inspired jewelry, understanding the materials you work with is crucial. Sheet metal plays a significant role in jewelry making, and it comes in various thicknesses or gauges. In this blog post, I’ll delve into the world of sheet metal gauges, with a special focus on copper and why it differs from ferrous metals.

The gauge systems for ferrous (iron-containing) and nonferrous (iron-free) metals differ due to historical practices and distinct metal characteristics.

Historical Development

The gauge systems for ferrous and nonferrous metals evolved independently based on historical usage and the unique properties of each type of metal. These systems were established before standardization efforts were widely implemented, leading to variations in measurement conventions.

Differences in Characteristics

- Ferrous Metals (e.g., Steel)

The gauge system for ferrous metals is often based on weight per square foot. This is related to the manufacturing processes and industrial applications where weight is a critical factor. The gauge of ferrous metals, like steel, is calculated by dividing the weight per square foot by the specific gravity of steel, which is approximately 7.85. For ferrous metals, thicker gauges are associated with lower numbers, indicating greater thickness and weight. As gauges increase, metal sheets get thinner. - Nonferrous Metals (e.g., Copper, Aluminum)

Nonferrous metals are measured using a gauge system that reflects the thickness of the metal. Unlike ferrous metals, the gauge system for copper is typically based on thickness rather than weight per square foot. The thickness is measured in inches or millimeters, and the lower the gauge number, the thicker the sheet. This system simplifies thickness representation, crucial in applications where conductivity, malleability, or weight matter.

Adaptation to Specific Needs

The distinct measurement systems for ferrous and nonferrous metals are adapted to the specific needs and characteristics of each type. For example, in applications like construction or structural engineering where the weight of the metal is a crucial factor, the gauge system for ferrous metals aligns with weight per square foot. In contrast, nonferrous metals, often used in electrical and artistic applications, require a system that accurately represents thickness.

Industrial Standards and Practices

Over time, certain industries and applications have adopted standardized practices for measuring both ferrous and nonferrous metals. However, the historical development and legacy systems still persist in many cases, leading to the continuation of different gauge measurement conventions for these metal types.

In summary, the differences in gauge measurement systems for ferrous and nonferrous metals stem from historical practices, the specific characteristics of each type of metal, and the diverse industrial applications in which they are used.